Services

What we do

ABCO is committed to providing quality, professional services and continuously strives to enhance our capabilities to meet the dynamic demands of our customers and our ever-evolving industry. Based in Brisbane, we offer a comprehensive suite of CNC services tailored to your exact machining requirements by way of milling and turning.

Specific services

ABCO Precision Machining can also supply:

Specific services

ABCO Precision Machining can also supply:

CNC Turning up to 1900mm dia x 4000mm long.

CNC Turning Centres up to 7 Axis.

CNC Milling up to 1200mm x 2400mm x 1200mm.

CNC Milling Centres up to 5 Axis.

Coordinate Measuring Services (CMM). Measuring stroke 2240mm x 1400mm x 1000mm.

Gear Cutting.

Keyways and Splines to 4000mm long (external).

Slotting and Keyways to 500mm long (internal).

Fabrication.

Robotic Welding.

Hard Turning and Milling to 65 HRC.

Induction Heat Treatment.

Plating and Specialised Coatings.

Hardness Testing.

Broken Tap Removal (spark eroding up to 35mm dia).

Fitting and Assembly.

Dynamic and Static Balancing.

Pattern Supply.

Reverse Engineering.

Upgrading Performance of Parts and Components.

CAD and Drafting.

Gauges, Jigs and Fixture Machining.

Finished machined casting and forgings to meet customers' requirements.

Metal Cutting of larger material.

Machine and /or supply components from Ferrous and Non-Ferrous material types and plastics up to 6000 kg.

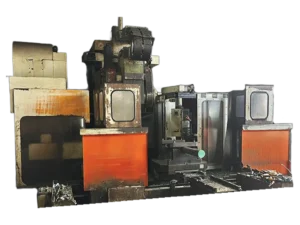

How we do it

ABCO has an industry reputation for quality. We use the latest CAD/CAM software to program and machine highly complex tool paths with high precision in economical time frames.

Mazak Integrex 400-IV

Mazak Integrex E-410H-II

Mazak Integrex E-1060VII - Twin Pallet

Mazak Integrex 200Y

Mazak Integrex J300

Okuma VTM-120YB

Makino H2210

SNK FSP-100V - Twin 1m Pallet (x2)

Mazak Super Quick Turn 30M

DN Solutions DNM 6700L

DN Solutions Mynx 9500

Litz LH630B - Twin 600mm Pallet

Mazak MTV-815/80

Niigata HN 100D - Twin 1m Pallet

Dainichi B105

Doosan Puma 400M

Hitachi 40G

Mitsubishi M-VT16A Vertical Lathe

Ferranti Merlin Mk2 CMM